C2 PROJECT

C2 Photo Album

album:August_2023

A view of the drain cock dropper link with a slight bend to avoid clashing with the brake hanger.

The pipe bender used to put a slight bend in the drain cock dropper link to avoid the front wheel set brake hanger.

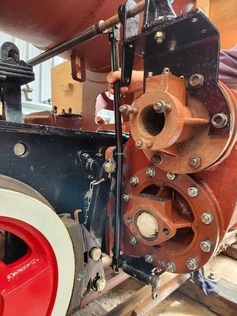

Drain cocks trial fit.

An afternoon walk along the cliffs above Boston Lodge. The roof of the C2 shed can just bee seen.

Pushing the bend out of the drain cock weighshaft bearing bracket (fireman's side) using the fly press. Following this, the bearings lined up with each other much better.

Compressed air hose attachments and valves on the tender steam brake cylinder ready for a break test at a later date.

Machining the reverser weighshaft keyways in the machine shop.

The fist key way complete on the reverser weighshaft.

Quarry Hunslet Hugh Napier on the back of the Woodland Wanderer empty coaching stock hitching a ride to Harbour Station for footplate ride duties over the bank holiday weekend.

Dave and new recruit Ed measuring up and making the bend which is required in the drain cock reach rod.

Olly and Tom take a break from shed duties to help clean up the safety chains between the loco and tender.

Olly and Tom take a break from shed duties to help clean up the safety chains between the loco and tender.

Following Andrew machining of the key ways in the drain cock intermediate weigh shafts, Dave 2 trial fits th keys and cranks.

Ed painted all the safety chain components on the Sunday. They will need another coat or two for full corrosion protection.

This view shows the proximity of the draincock reach rod with that of the reverser reach rod. Careful measuring has taken place to ensure that they will not collide.

Here can be seen the new piece of drain cock reach rod which has been carefully bent into shape (behind the reverser crank) ready to be connected at a future working party.

Trial fit of the screw reverser and drain cock levers in the cab.

Bespoke boring bar made by Erle for machining the internals of the turbogenerator governor valve. The tool steel was cut to the required length before being used.

Fitting the split gland rings on the back of the turbine.

Graphite carrier block in position on the turbine.

Graphite carrier block.

Boring bar about to machine the inside of the bronze regulator sleeve.