C2 PROJECT

C2 Photo Album

album:December_2025

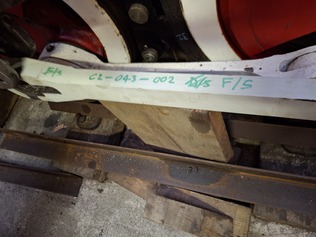

Measuring and final machining of the bottom slipper in the fireman's side cross head. Here shown with a parallel clamped in place to help measure the alignment of the slipper to the piston rod. Dec 2025

Pressing the big end bearing outer races into the connecting rods on the hydraulic press. Dec 2025

Pressing the big end bearing outer races into the connecting rods on the hydraulic press. Dec 2025

The connecting rod ready to accept the new big end bearing outer race. Dec 2025

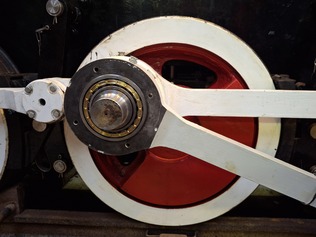

Driving crank pin cleaned up ready to accept the big end bearing inner race. Dec 2025

The big end inner bearing races lowered into the oil bath for heating. Dec 2025

Heating the oil bath. Dec 2025

Erle fitting the heated big end inner bearing race onto the fireman's side driving crank pin. Dec 2025

The driver's side connecting rod big end roller bearing fitted to the crank pin. Dec 2025

Expansion link pivot sleeves fitted on the hydraulic press. Dec 2025

New piston gland made by Jack. Dec 2025

New piston gland made by Jack. Dec 2025

Measuring the position of the connecting rod to the crossheads. Dec 2025

(above) New piston gland made by Jack. (Left) New and old piston gland side by side. Dec 2025

Taking measurements in the gloom while the electicity poles to site were replaced. Dec 2025

Snakes alive! - This snake was spotted guarding the entrance to the carriage works between Christmas and New Year. I wonder if Glen left it there to discourage anyone from entering the carriage works while he was off work for Christmas? I certainly I gave it a wide birth. Dec 2025

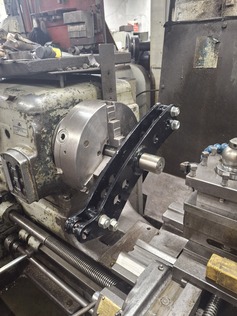

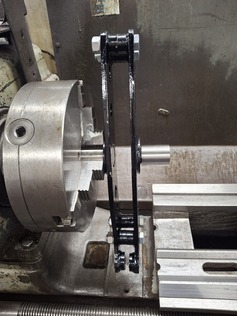

Expansion link carriers mounted on the lathe to machine the stainless steel pivot sleeves. Dec 2025

Expansion link carriers mounted on the lathe to machine the stainless steel pivot sleeves. Dec 2025